Howdy 👋

We found another awesome newsletter!! If you want even more climate in your inbox check it out below!

The Green Techpreneur helps climate tech entrepreneurs succeed by showcasing the stories of extraordinary entrepreneurs and investors striving to create a sustainable world. Sign up if you want to learn about business growth and attracting investors. It’s great for cleantech connections, advice, ideas, and mentors. Every edition is actionable, insightful, and fun!

– Swarnav S Pujari

In Your Inbox: Reservoirs as an ESS; Phytoplankton for carbon sequestration; Elon and water rights; Portable battery price parity

For the world to become climate neutral by the coming 30-40 years, enormous amounts of renewable energy will be deployed. The transition has already started. As a result, large daily swings of energy generation occur in our system, and in some markets, we see negative electricity prices. To balance these swings into a stable energy generation, energy storage is crucial. In other words, the storage market has barely taken off.

Rikard Tullberg, the CFO of Pumped Hydro Storage, discusses how he envisions the future of energy storage.

Pumped Hydro Storage (PHS) is a developer of large-scale energy storage projects. We are here to propel the transition into a carbon-free planet by providing one of the world’s most sustainable and cost-effective energy storage solutions.

By benefitting from the decades-long development of pumped storage technology and utilizing it in underground mines, PHS creates a state-of-the-art storage solution without the need for any rare earth metals. By replacing gas peaker-plants, our large-scale projects can reduce their emissions by up to 200 thousand tons of CO2 per year.

PHS incorporates the whole value chain in the delivery of a successful energy storage project, including project development, permitting, construction, realization, and operation. As such, we own the project and optimize it through all phases until we pass it over to an investor at the start of operation.

As energy systems will be more reliant on intermittent weather-dependent renewable energy, the energy off-takers and grid owners who warrant a stable energy generation to their customers need to find a solution to secure a stable energy output. As such, the demand for a cost-effective long-duration (4-12 hours) energy storage will heavily increase to meet the coming need to balance the ongoing rush of deployment of renewables into the system. And this is where PHS’ solution comes in.

The land/mine owners get a second life of their mine, transforming it from a depreciated asset/liability into a valuable asset again. Meanwhile, project owners/investors will gain a financial yield of 5-10%, in parity with other large-scale renewable energy projects, such as wind and solar projects.

The renewable energy transition has already begun, but we have only seen the start of it. According to sector experts, renewable energy penetration will increase exponentially during the coming 30 years.

As such, lots of different technologies are under development to cater to the huge demand for energy storage that is to come. However, many of the technologies usually come with an obstacle – either they depend on rare earth metals, have a low-efficiency rate, or are very expensive. They can also use a less environmentally friendly technology or be in an early stage of technical maturity. When storing energy through pumped storage, we use something as natural as regular water as the energy carrier and generate energy by utilizing gravitational forces between two reservoirs at different heights.

Hydropower and pump technology are both two very mature technologies, benefitting from decades-long development. The oldest pumped hydro facility that is still active was developed in 1907. However, as the demand for long-duration energy storage hasn’t been as urgent until recent years, the deployment of the technology has been limited in the western world in the last decades. Thus, PHS’ initiative to combine the technology and deploy it in underground mines could be called a “renaissance” of a mature technology, by commercializing it in a new market environment.

The market for energy storage will be enormous – there will be many solutions that will cover the entire demand for renewable energy. I believe that scaling existing technologies, such as hydropower, is the path forward to a sustainable future. The trick is finding the right capital to support these projects and efforts.

Sign up for The Impact and learn the perspectives behind the latest sustainability trends

This week, I had the opportunity to chat with Philip Kithil, CEO, and Salvador Garcia, CRO, from Ocean-Based Climate Solutions to chat about how their Autonomous Upwelling Pump systems are pumping deep-ocean nutrient-rich seawater to fertilize phytoplankton on the ocean surface to sequester carbon.

Philip: “The climate was front and center from day one. What sparked the idea of upwelling cold water to the surface was Hurricane Katrina in August 2005, one of the strongest hurricanes to hit the US Coast. Colder ocean waters slow down hurricane intensity. So our team ran some tests in the Gulf of Mexico in October 2005 to see if we can bring up cold water to the surface, and it worked! That same month, I had a phone call with Rod Johnson and Tony Knap at Bermuda Institute of Ocean Sciences about upwelling nutrients. They invited our team in December 2005 on a cruise to test the pump. And it worked! Since then, our technology has evolved into what I think is a silver bullet for climate change to get us back to 300 parts per million CO2 by 2100. And I’m firmly convinced we can do that. I’m a serial entrepreneur; this is startup number six since 1972. Previously worked in and sold my automotive safety smart airbag technology and started the predecessor to OBCS, Atmocean, in 2006.

Salvador: Marine snow is dead, eaten, or excreted phytoplankton and fish. It’s chunks of that organic biological matter that gently falls to the seafloor. It also serves as nutrients for deep-ocean creatures that ultimately start piling up on the seafloor, turning to what we know today as limestone. For example, The White Cliffs of Dover is an example of limestone peeking out of the ocean, shelled organisms that fed on phytoplankton over millions of years, billions of years.

Philip: And so look out the window you see a leaf on a tree. That’s a photo synthesizer. It takes in CO2 from the atmosphere, takes energy from the sun, takes water from the tree’s roots from the ground, and does photosynthesis and gives off oxygen. Phytoplankton is the very same thing, but they’re in the ocean, and they’re microscopic; they’re not the size of a leaf on a tree. So it’s the same process. It’s just out in the ocean, and it’s huge because of the scale of the oceans and the doubling time of phytoplankton. They double in mass every 24 hours. And so our solution is a much faster process out in the sea, which is 70% of Earth’s surface, absorbing CO2 through photosynthesis converted into solid carbon, which becomes marine snow. It then sinks to the seafloor while feeding the fish and the ocean’s mid-level and deep-level life forms.

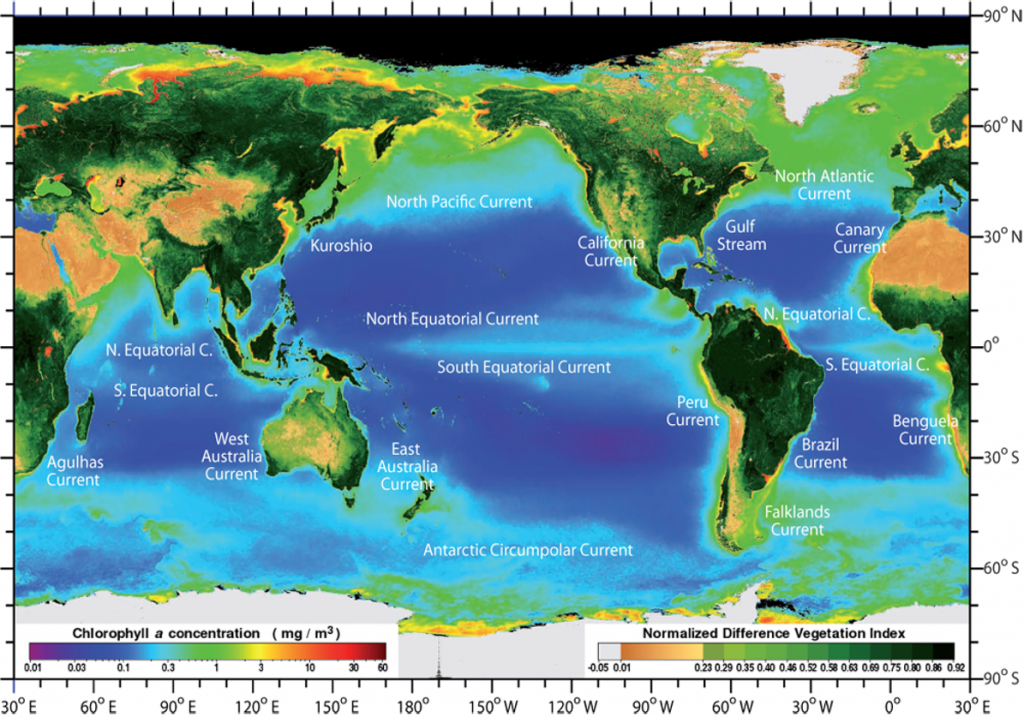

Salvador: 99.9% of all CO2 is held in limestone deposited on the seafloor. It got there from phytoplankton and fish over millions of years. Our climate solution is to trigger phytoplankton blooms year-round in the ocean gyres, far offshore. There’s little to no phytoplankton in the center of the ocean gyres – because the sunlit upper ocean is starved of nutrients – it’s a low nutrient, low chlorophyll zone. Due to the warming of our oceans caused by excess atmospheric CO2 absorbing heat from the sun, about 40% of the world’s phytoplankton has disappeared since 1950. So the lack of phytoplankton contributes to more atmospheric CO2. Because our technology is just a one-time upfront cost yet lasts 80 to 100 years and is powered by free renewable wave energy, the cost per ton of CO2 removed decreases by half every year.

Philip: An AUP is designed to trigger year-round phytoplankton blooms, extending more than 500 meters (1,640 feet) into the nutrient-rich layer of our oceans to pump up, or upwell, cold nutrient-rich seawater to stimulate phytoplankton growth; powered entirely by 100% renewable ocean wave energy. An AUP is a buoy tethered to a 500-meter long tube with a one-way valve at the bottom, weighted by a two-ton weight, to keep it vertical. As the buoy rises on a passing wave, the entire tube also rises, closing the valve at the bottom and moving the water upward by the height of the wave. On the wave downslope, the whole tube sinks, opening a valve at the bottom filling the tube with that nutrient-rich seawater, and releasing the topwater into the sunlit zone, where it quickly triggers photosynthesis and phytoplankton growth.

Salvador: The North Pacific and the subtropical South Pacific are the best starting locations for our application. Due to its vast size and slow-moving circulation patterns, the Pacific Ocean contains the oldest ocean water, giving us 1,000 plus years of storage at depth. Furthermore, the North Pacific is a low nutrient, low chlorophyll zone – perfect for our application. The subtropical South Pacific is a high nutrient, but low chlorophyll zone, meaning the sunlit surface is ready to go once critical trace minerals (such as iron) are upwelled. So the same application will work there. Our AUPs can be deployed in the center of any ocean gyre where there is low phytoplankton. However, it makes the most sense to start with where there is the most potential for long-term storage.

Phil: What we have done is engineer the Autonomous Upwelling Pump for extreme durability. The ocean is the harshest environment on Earth. Huge waves, bad weather, wind, you name it. Now you have to realize that 99% of our device is underwater, so it’s not going to see those winds and most of those extreme events. The weather makes no difference. AUPs are very rugged, durable, long-lasting, and autonomous, meaning they are free-drifting with the ocean currents. That reduces the stress compared to if each AUP was anchored to the seafloor. So by letting it drift with the currents, you’re eliminating more than 50% of the harshness of the ocean environment.

Salvador: Fisheries also benefit from the AUPs being free-drifting, with localized phytoplankton blooms traveling with the currents of the ocean gyres. Fisheries will emerge, develop or translocate within the arrays of AUPs. This benefits fish, tuna, sharks, dolphins, and whales. Think of drifting oases of vibrant sea life in the middle of ocean deserts! Other co-benefits are jobs at port cities where AUPs are deployed – our technology will spur a new industry. Another benefit is its low cost per ton of CO2 removed. AUPs are designed to operate for 80-100 years and remove approximately 257 tons of CO2 every year, making the long-term cost under $10 per ton of CO2 removed.

Phil: So our number one challenge at the moment is gaining the confidence of investors. The second is to sign up corporations to become net-zero CO2 footprint within 10 to 15 years. But this will happen on its own as there is such a high level of public and shareholder interest in solving the climate crisis. To help these corporations, we have a funding methodology called Stock for Carbon. Public companies can purchase AUPs at no cash expense by paying using their publicly traded stock. Because our solution is nature-based, we are taking advantage of biological effects in the open ocean, which are currently untapped, meeting the criteria of “additionality” – the CO2 removal would not have happened without our involvement. Also, we can measure and verify the CO2 absorbed by the phytoplankton using biogeochemical ARGO sensors. These are the robotic floats that can measure ocean chemistry and carbon sequestration from 2,000m deep up to the surface. And then, we have the business model that makes it fundamentally doable with many corporations who are now very much wanting to become carbon neutral.

Salvador: Another challenge is governance. It’s in the open seas; it’s not near the coast. So we do follow all the laws that we’re aware of in terms of executing what we do in international waters. Still, perceptions and arguments do arise about our method. Another challenge is or will be public acceptance of our practice on our implementation. We want to be close with all stakeholders, the world, and the public. One of our fundamental values is transparency. The data that the ARGO’s provide is publicly available online. Anyone who desires to review the data our AUPs produce can access it – so independent scientists or organizations can verify our work.

Philip: Because we partner with phytoplankton, and our technology is modular. AUPs are not big devices. The ocean is vast. It’s possible to produce and deploy a large number of AUPs and space them in the open ocean so they are invisible from an airplane, not hazardous to shipping, and sequester CO2 in the deep ocean and help feed fish! Also, they oxygenate and cool the upper ocean and provide jobs at port cities! The oceans hold 50x more CO2 than our atmosphere and 20x more than on land. The ocean is the place to solve climate change, and this is the technology that can do it at the lowest cost with the least risk.

The ocean is a body for change, using its lifeforms to mitigate the climate crisis. Utilizing this seemingly terrestrial process in “soil” rotation of phytoplankton to create marine snow in bulk, there is significant potential to not only remove carbon from the atmosphere via photosynthesis but also create a healthier ocean as a result.

As for whether or not this technology is a silver bullet…well let’s wait and see. Combating climate change is a multilateral approach across all industries in all sectors in all walks of life. No one is immune to it. No one is excused from it. If this technology is a silver bullet, it will certainly help speed up the rate at which we can remove CO2 from the atmosphere.

Talking batteries camping is not an impactful climate solution. It falls in the category of ditching plastic straws and toting around reusable cutlery: well-intentioned, but mostly meaningless.

If this niche crunchy granola camp-gear-lovers market matters at all to the planet, it’s because of this: Portable battery storage is exactly the same product as residential energy storage, just tinier. If portable energy storage looks reasonably attractive, so should home energy storage.

So I descended into a clickhole comparing portable batteries. In browsing, I mostly considered the cost. It’s not just that I’m stingy; it’s also because of something Saul Griffith said recently that stuck with me:

“At the end of the day, you don’t fix climate change unless everyone can afford it. And I think that sobers you up straight away”

Decarbonization solutions have to be affordable to become mainstream. Yes, that’s difficult, but what a wonderful situation to have equity be a prerequisite to wholesale decarbonization.

When charged, batteries have an amount of energy inside them. The full amount of energy they can hold is called the battery’s capacity. You can think of a charged battery as a full bathtub.

Batteries also have a power rating. This determines how quickly you can grab power from the battery and shove it in your phone, computer, or car. You can think of the power rating as the size of the drain in the bathtub — bigger drain, faster flow out of the tub.

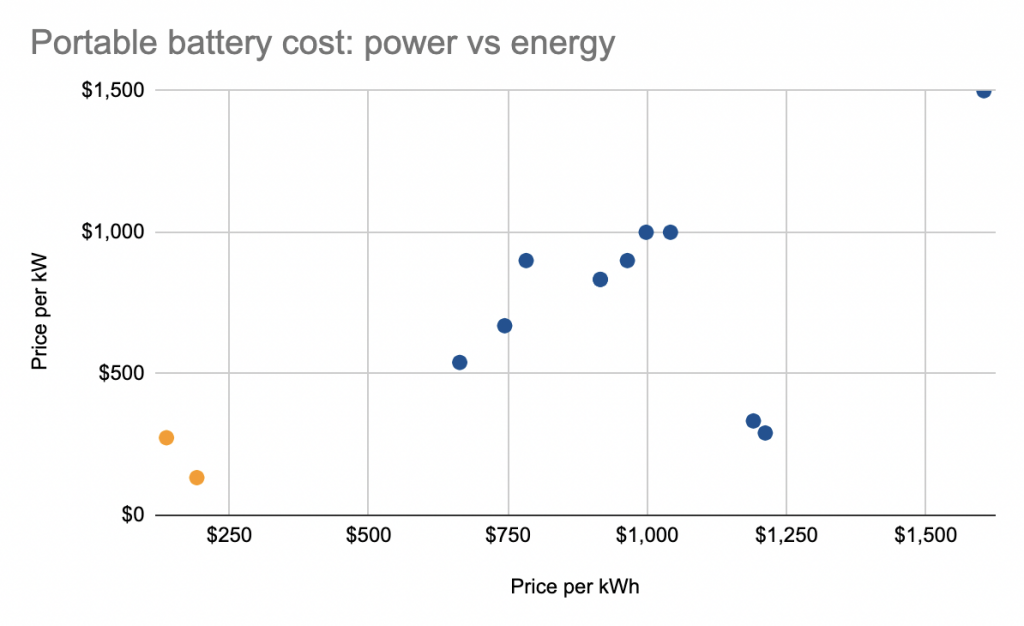

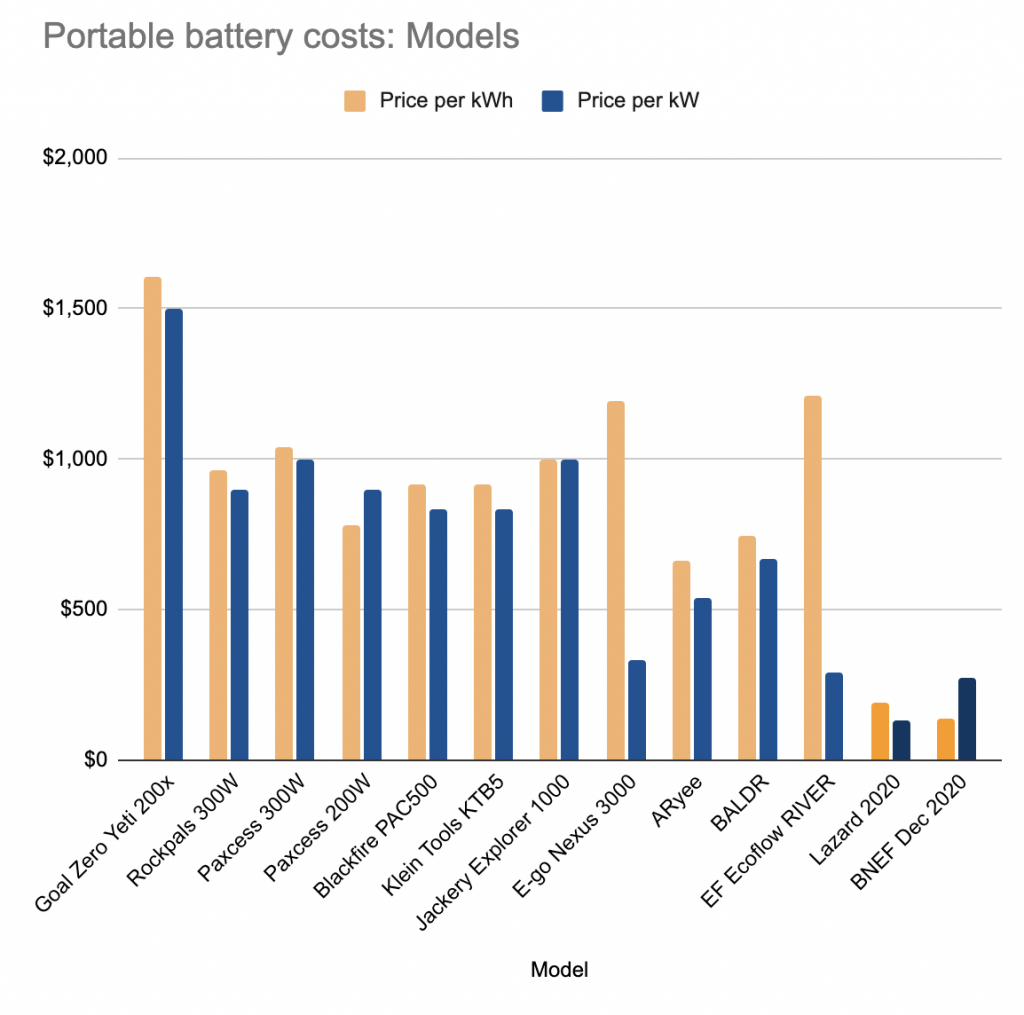

Both of these quantities have a direct impact on how you use your battery, so I calculated the cost relative to using each.

It’s hard to compare battery costs when they have different capacities and power ratings. You can get around this by dividing by the capacity or power rating. This is what I did below.

The orange dots are industry averages for utility-scale batteries, while the blue dots are for portable batteries that you and I can buy. Here are a few takeaways:

If you’re curious which dots above corresponds to which model, the answer is below. I also included the utility-scale battery costs, for a fun comparison, on the right side.

Data

Here’s my spreadsheet, if you like to see the data on which the charts above are based.

Editors: Swarnav S Pujari, Daniel Kriozere Writers: Matthew Morris, Austin Park, Marianne Lehnis

If you aren’t absolutely thrilled with The Impact, reply and let us know why. Or you can unsubscribe from all updates by clicking here.

Copyright © The Impact 2021. All Rights Reserved || 19 Morris Ave, Bldg 128, Brooklyn NY 11205

Develop your market map of up-and-coming climate startups and market opportunities by subscribing to our weekly newsletter for free.