🤔 Well it’s September now…I guess 2021 is almost over. Which means an onslaught of announcements from our team on projects we’ve been spending nearly the ENTIRE year on.

I can’t wait to share these projects with you all – we know it’s going to help the climate community significantly.

THE TL;DR 💨

- Understanding how much CO2 is actually in the air is critical to understanding if reforestation is alone enough for decarbonization

- Measuring the amount of carbon in the air and the amount removed is critical for carbon capture applications, not just temperature increases

🚧 Yotta Energy is making storage easy to deploy on commercial buildings

- A new energy storage architecture brings battery storage capacity below solar panels on commercial installs

- This system – much like enphase’s approach to modular, panel integrated inverters – enables installers to deploy cheaper solar plus storage systems

⚗️ Vistex Composites: enabling broader adoption of composites with improved manufacturing methods

- A new process has been created to reduce the time and complexity in traditional composities manufacturing

- A mixture of software plus process delivers significant efficiency in composite manufacturing

🌳 CARBON CAPTURE

Everyone Should Understand The Carbon Cycle

By Stephanie Zulman

Earth’s burning. Literally. And finally, we are beginning to see large swaths of our population turn their heads towards the threat of increasingly obnoxious global warming and begin to ask what they can do to help. The best way that I think I can add value is by helping address one of climate change’s most time-sensitive variables: the atmospheric oversaturation of carbon dioxide. When I brightly proclaim my aspirations to have a career in this less popular Earth-saving field called carbon capture, I’m most often met with blank stares and uncomfortable chuckles as if I’ve suddenly started speaking in tongues. So, I’ll usually give a quick explainer: “our skies are already oversaturated with carbon dioxide and other harmful particulates, and it’s crucial to suck as much of it out as we can ASAP to survive climate change.“

What has really fascinated me is that the second reaction I’m met with most often is: “Well, what about the trees? Can’t we just plant more trees?”

I usually struggle at this point with how to articulate a neat description of the practical and scientific reasons why a mass effort to plant trees will not simply solve this issue, or whether I should just scream “NO” and find the nearest bag to hyperventilate into. The global warming puzzle we now must solve is complex. Many of its pieces are wrought out of fires that we have forged ourselves. Others are linked to the very fabric of the natural world and its codependent ecosystems.

Carbon capture, an essential tool that’s finally starting to receive the attention it deserves as a necessity to combat climate change, is still a field that much of the population does not understand. Even without the heavy touch of humanity-induced climate change, capturing carbon atoms is still a pivotal component of Earth’s interconnected carbon cycle. It works well independently and can put up with a moderate number of unasked contributions. Understanding how Earth did it before we came around messing up the balance and needing more aggressive means to control our pollution propensity is the first step to appreciate why we should really all become some type of tree hugger.

The Earth & Atmosphere's Operational Relationship with Carbon

The Science Behind the Cycle

To appreciate the impact of trees, one has to first understand what their role is in the big picture of Earth’s normal operations. So, let’s talk about the carbon cycle. On the most basic level, photosynthesis (CO2 absorption) and respiration (CO2 release) are the two fundamental processes involved in exchanging carbon atoms between Earth’s atmosphere and its terrestrial biosphere (aka land-based vegetation). Through the process of photosynthesis, plants emit oxygen and store carbon to become what we call a carbon sink. Respiration provides what’s known as a carbon source. The oldest, expected emitters are animals and slain/decaying plants. However, older and larger concentrations of carbon, previously undisturbed until human intervention, have become a more venerable carbon source. Our impact has been so significant that we’ve even given our pollution contribution from human activities its own name: anthropogenic carbon emissions. In the past 80,000 years, the planet hasn’t seen anywhere near as high a concentration of particles in the atmosphere as there are right now.

The Scourge of Anthropogenic Emissions

The carbon cycle does the best that it can to balance the massive excess of carbon atoms we’ve been emitting. The terrestrial biosphere absorbs approximately one-fourth of anthropogenic CO2 emissions annually. The ocean absorbs another fourth, and the remaining half of our emissions remain in the atmosphere. While there are many other polluting particulates, CO2 is a favorite to focus on because it accounts for the highest percentage of emissions at about 80% and has been proven to be the key gas that sets the Earth’s temperature. It stays in the atmosphere for the longest period of time(scientists estimate this lifespan to be between 300 and 1,000 years), and hotboxes the Earth by trapping heat that would otherwise escape and re-emitting it back down to us.

A resounding theme we can see in nature from a macro to subatomic particle level is an innate propensity for homeostasis. Without our help or knowledge, our planet has already figured out many clever mechanisms that it deploys to create its own checks and balances system. When temperatures rise, the rate of photosynthesis and respiration naturally increase. However, at the aptly named climate tipping point, this balance is predicted to cease. At this point of atmospheric oversaturation, although the rate of respiration will continue to function normally, photosynthesis will begin to decline. So, as the scales become imbalanced, we’ll find that we all have much less oxygen to go around.

Outlook

Measuring carbon levels is important because it is our planet’s natural thermometer. Earth’s atmosphere regulates temperature and will respond to extreme imbalances much like how the human body does once it reaches an internal temperature of around 104°F (40°C): the major organs that give us life will begin to break down. At 107°F (41.67°C), the body’s most likely not going to bounce back. Scientists have determined that after the Earth’s temperature rises past 2°C (which is expected to happen by the end of this century), the planet will experience a similar phenomenon. We’re currently predicted to hit the 1.5°C marker by 2030, so expect even bigger, more dramatic changes on the murky, clogged horizon.

The doomsday level temperature increase is equivalent to a rise in the atmospheric concentration of CO2 of between 425-450 parts per million (ppm). Before humanity went all-in for fossil fuels, preindustrial levels of carbon dioxide were 280 ppm. According to NASA’s James Hansen, a top climate scientist, the “safe” upper limit was really 350 ppm. Earth, by herself, needed 20,000 years to go from 185 ppm to that preindustrial 280 level measured in 1850. According to Hansen’s op-ed, at 550 ppm, we’d reach catastrophic temperatures previously last seen when sea levels were 80 feet higher. So, we all have that to look forward to, too.

According to CarbonTracker, the global monthly mean of anthropogenic emissions sitting in the atmosphere was 416.49 ppm as of May of this year. Overall, the data shows an easy to interpret summary: the concentration of particulates in our atmosphere is consistently still on the rise every single year.

With this newfound appreciation of the carbon cycle’s importance in keeping our planet cool, we can see how and why our pollution propensity is pulling us towards catastrophic climate change. There is an urgent need to start pulling as much carbon out of the atmosphere as possible. Now begins our tree-hugging trekk to appreciate why we must both plant and protect trees, and deem the strength of their role as a carbon sink. For the sake of simplicity, this series will only examine the tree-related variables helping and hindering our progress to dial back Earth’s rising fever.

⚡ DISTRIBUTED ENERGY RESOURCES

Yotta Energy Is Making Storage Easy To Deploy On Commercial Buildings

By Swarnav S Pujari

The US solar industry grew by 43% in between 2019 and 2020. Most of the newly added capacity is likely coming from utility scale deployments or residential installs.

Ignoring the commercial and industrial (C&I) space for solar has become almost a status quo. While many in the industry recognize the hugely untapped opportunity of deploying solar plus storage on C&I properties – the challenges it can bring tend to drive installers to look towards the utility scale deals or focus on residential projects.

The reason C&I solar plus storage projects get avoided is because they tend to have the permitting complexity of a utility scale project, but the “smaller” check size and behavior of a residential project.

Pair this with the rise of more energy storage systems (ESS) being deployed and utilities wanting property owners to prioritize buying solar plus storage – for grid management purposes – and you run into multiple new challenges:

- Financing C&I projects

- System design and standardization (modularity)

- Keeping project economics reasonable when including ESS in project bids

- Enabling ease of deployment and maintenance of a solar plus storage

What is Yotta Energy?

Yotta [yah-tah] Energy – founded by Omeed Badkoobeh and Vikram Iyengar – is building a solution to address the system design and standardization as well as the project economics challenges plaguing solar installers in closing more deals in the C&I market.

They do this through a solar panel integrated battery system.

Much like how Enphase enabled the modularity of deploying solar on residential properties, Yotta Energy is bringing the same approach to deploying energy storage effectively.

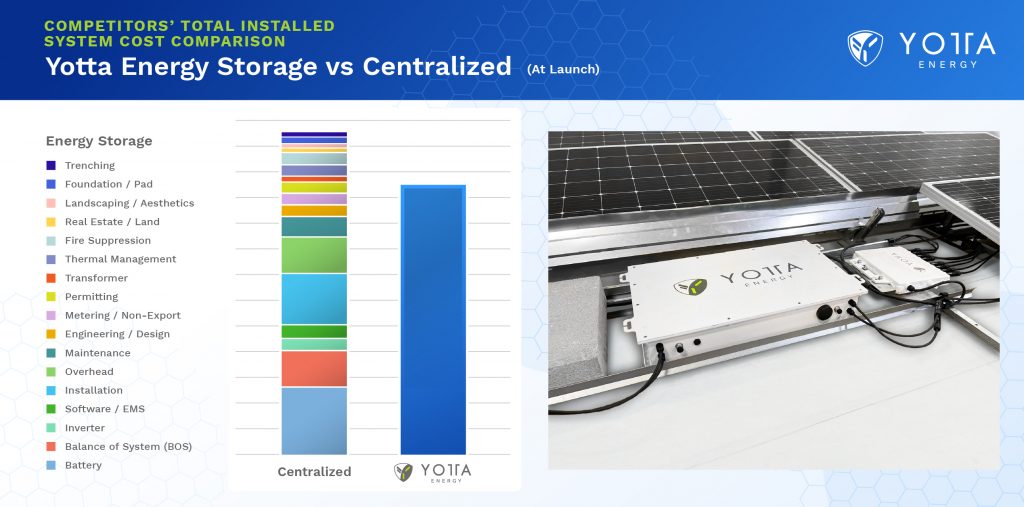

The hidden cost of commercial storage projects

Many people see the battery cost or the inverter as the primary driver in making projects expensive in small commercial and industrial battery projects. However, as shown by the graph it’s ancillary protections and installation that can drive the cost through the roof.

The benefit of taking a modular and panel based approach – as Yotta is doing – is that it allows developers to now avoid most if not all of those “extra” costs associated with these projects.

Yotta could create MWhs of easy-to-deploy storage capacity - which may position them as a leading player in deregulated electricity markets

The monetization of energy storage through VPP contracts or by trading flexible capacity on the wholesale markets (post FERC 2222) makes Yotta a really interesting player going into the future.

The ability to rapidly deploy low cost energy storage in a market which struggles to adopt energy storage (small commercial and industrial) means they’ve discovered a way through their system architecture to bring new capacity into the marketplace.

The potential to play in these markets and generate additional revenue from the creation of this capacity makes them positioned as a strong candidate even as other similar technologies may prop up.

Outlook

Yotta excites me given their key focus on servicing the small commercial and industrial niche. This sector has remained largely untouched from a financing, install base and adoption front purely because economics have been limited even with tax incentives.

New technological approaches like Yotta’s are what are needed to open this sector up.

Sign up for The Impact and learn the perspectives behind the latest sustainability trends

🚀 STARTUPS & TECH

Vistex Composites: Enabling Broader Adoption of Composites with Improved Manufacturing Methods

By: Daniel Kriozere

With a world in constant need of lighter and stronger products, advanced composite materials (including carbon-fiber) hold great promise. However, traditional composites manufacturing has remained nearly unchanged for the last 50 years; making it extremely expensive, labor intensive, and environmentally taxing. It’s time for change.

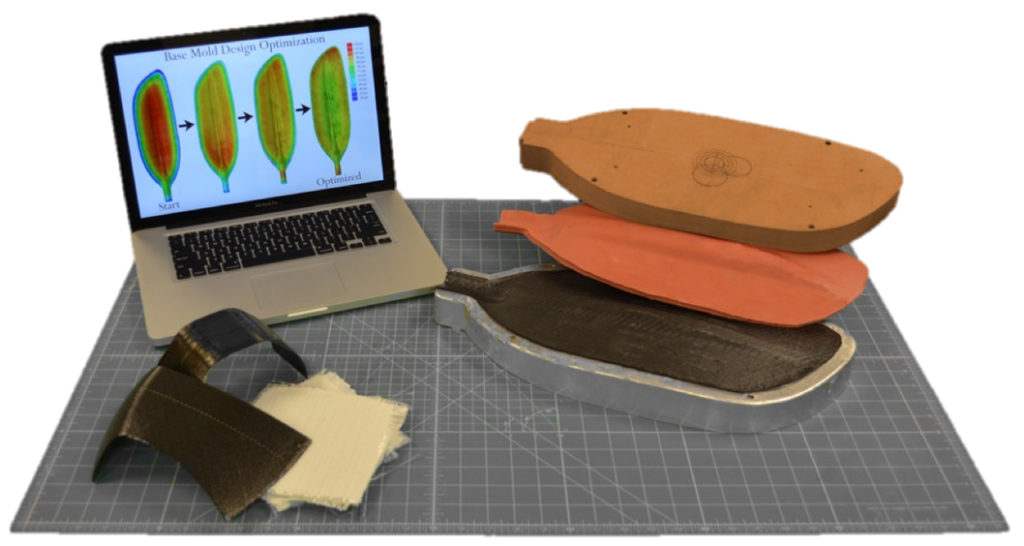

Vistex Composites offers a patented manufacturing process that has helped usher in that change. Vistex utilizes proprietary software to optimize custom molds designed to provide superior performance in composites manufacturing.

What problem is Vistex Composites trying to solve? How are you solving the problem?

Traditional composites manufacturing is slow and expensive because it relies on tedious, labor-intensive processes. The other piece is that traditional manufacturing also creates waste.

Vistex Composites has developed a process, using a customized Pressure Focusing Layer, that achieves the uniform pressure and uniform temperature required to make a composite by a much more efficient approach, as compared to the current gold standard, autoclaving. We have developed computer software and optimization algorithms to design and optimize manufacturing molds. Part of the technology is that we’re able to rapidly heat and cool our molds, which increases throughput. Alternatively, we can keep molds at temperature and cycle material in and out. There’s also an added benefit – if we can increase our throughput, we can make more products on a given mold. If you can reduce the number of molds that are needed for a production run, that can be a substantial amount of money.

How are you thinking about and quantifying impact metrics?

We quantify our metrics in a few ways, and it depends on the specific needs of the customer.

Some customers are very interested in the energy-savings aspect of our technology. We’ve demonstrated that we can reduce energy consumption by 90%, or even more in some cases. We’ve quantified the amount of energy savings – for one of the products that we produced using our technology it was found that for every 150 square feet of product (approximately 150 kayak paddles) it saved the amount of energy that the average US household uses in one year. Multiplied across entire industries, the energy and environmental benefits are staggering!

But the most important metric for customers is always cost. Vistex is able to save money both in capital equipment (Cap-Ex) and in the process of producing the good (Op-Ex). For example, companies that are looking to expand their capabilities often spend upwards of $10M+ to outfit their facility with a large autoclave but we could achieve similar throughput capabilities with two or three manufacturing cells costing just $200K each. Because Vistex is able to reduce or even eliminate many of the tedious manual processing steps and disposable bagging materials used in competitive processes, we are able to significantly increase throughput while reducing production costs. For one of our customers, it is the reduced complexity of Vistex’s processing steps that is leading to adoption. As the ability to combine Vistex’s production technology along with robotic automation enables very repeatable processing, and results in exceptional quality products.

The other metric we’ve found to be critical for our customers has been time-to-market. For a company that’s developing a new product, we can engineer a custom mold for them to make their product properly and correctly the first time, as opposed to competitive processes that can take many months, or years to implement. We have one customer we’re working with now who had spent years trying to get another method to work. They just kept wasting time and money with their old techniques, years of design iterations and defective parts later, they’ve finally made the switch to our process and we have solved their problems in under 6 months!

Are customers open to adopting your technology?

Early on, when we were just getting started, this was difficult, as customers saw a new technology as risky. We started out by validating our technology across a wide range of industries like sports equipment (kayak paddles), safety products (helmets) and wind energy (blades). We are working on a lot of exciting opportunities right now. We are currently producing components for UAV/UAS (drone) systems, developing automotive components in partnership with OEMs and materials companies, and designing and building the next generation composite booms for NASA.

We’ve also recently signed a Joint Development Agreement with one of the world’s largest materials companies in order to pursue specific opportunities in the aerospace market that have incredible growth potential.

What does competition look like?

There’s a handful of other technologies and methods that people are trying to develop to displace the autoclave, which is just a large, pressurized oven. Techniques like resin transfer molding (RTM) offer some throughput advantages over autoclaving, but they often struggle with defects in the form of voids, and many industries simply can’t have that. Different materials like sheet molding compounds, can be formed into the product shape very quickly, but the size of the fiber reinforcements that can be included in these materials is small, and the ratio of the fibers [the portion of the composite that gives the product its strength] in the material is low.

Where we are differentiated in the market is that we offer our customers scalable production volumes, but with low CapEx and OpEx. We’ve also demonstrated that we are able to handle products with complex features such as undercuts, that other techniques simply cannot achieve.

After Vistex Composites succeeds, what does the future look like? What's next after that, in terms of the market?

We will make composite products more accessible for more markets. These are strong, lightweight products that can offer so many benefits, like fuel savings and emission savings. What’s exciting for us is we’re able to save energy, save pollution, save costs in the manufacturing process, which then enables those products to save more energy, reduce more emissions. It’s like a snowball effect, where we enable those environmental benefits on the production side, which allows for better products while they’re in use.

Outlook

Vistex Composites is solving a big problem for the manufacturing sector. Traditional methods and processes are lengthy and expensive. As a result, only large companies can afford these high cost and slow manufacturing processes. However, some of these companies are now demanding a higher throughput. For instance, the automotive market is looking for a one-minute effective cycle time. Vistex Composites brings speed efficiency to the sector, and their thermoplastic composites are also recyclable.

Writers: Swarnav S Pujari, Daniel Kriozere

If you aren’t absolutely thrilled with The Impact, reply and let us know why. Or you can unsubscribe from all updates by clicking here.

Copyright © The Impact 2021. All Rights Reserved || 19 Morris Ave, Bldg 128, Brooklyn NY 11205