In Waste to Carbon Credits 101: Biomass-Based Carbon Removal, we covered the absolute basics of biomass-based carbon removal and its potential impact.

Let’s revisit: On a high level, how does it work, and what factors influence how well it works?

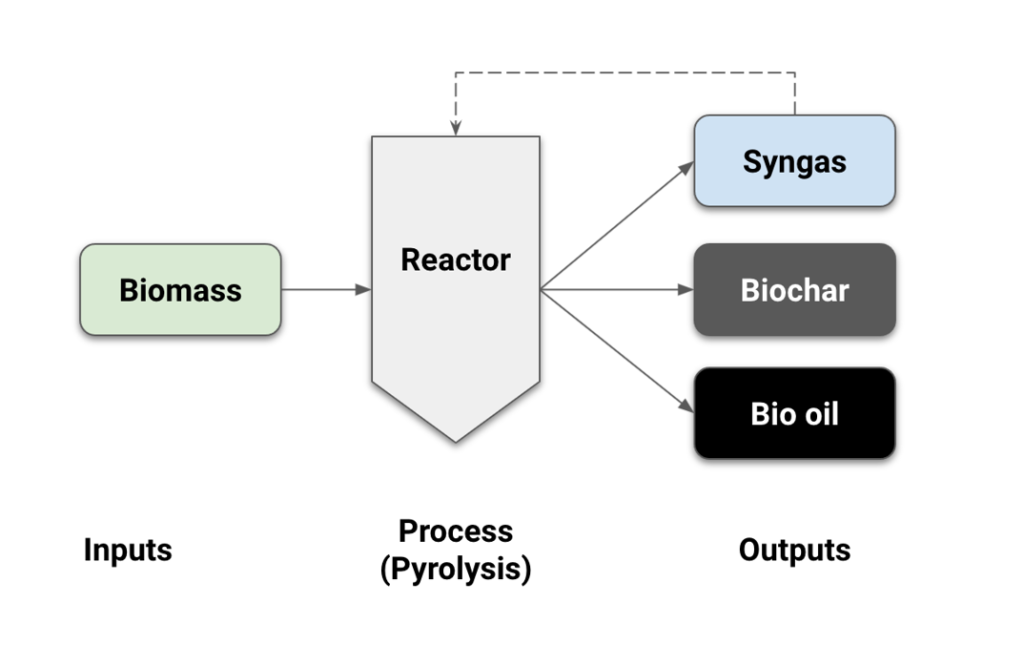

Waste biomass input -> process (pyrolysis) -> CO2 removal via conversion of biomass to a stable output (biochar and bio-oil).

We can think of these different components like a recipe. Similar to how the ingredients, bake time/temperature, and food storage impact the longevity and deliciousness of your favorite cookies, the feedstock, process, and application of the final material play a role in determining the carbon removal benefits of biochar and bio-oil, and co-benefits of biochar.

Biomass:

This can mean any organic matter to be used as fuel/feedstock for a process. Many companies have turned to waste biomass as the source material for these processes. Examples include timber byproducts, agricultural waste/crop residues such as walnut shells or corn stover, or even sewage waste.

Feedstock variables to consider include:

- Availability: How reliably can the feedstock be sourced?

- Processing: How well it can be processed (e.g. does it need to be dried or chopped)

- Location relative to processing plant: Will the feedstock need to be transported long distances for processing?

- What would have happened to the biomass if it was not diverted for carbon removal/biochar production? This is critical for determining additionality.

- Nutrient mix: this was found to have the biggest impact (versus pyrolysis type and temperature) on biochar properties with respect to its use as a soil amendment. Conversely, utilizing more nutrient feedstocks such as manure or sewage waste may increase the risk of toxic compounds in the biochar produced.

Process:

Pyrolysis, a process that involves heating the biomass with low or no oxygen, yields biochar, bio-oil, and syngas. Gasification is a similar process you’ll often find mentioned alongside pyrolysis – this also produces biochar but with much lower yields, and is more relevant for using biomass to produce syngas for energy production.

Variables to consider for pyrolysis include:

Type of process:

- Slow pyrolysis: produces more biochar (400-600C, 20-50% biochar yield, residence time hours to days)

- Fast pyrolysis: produces more bio-oil (400-600C, 5-20% biochar yield, residence time seconds)

- Torrefaction: Also known as mild pyrolysis. Produces more biochar (~200-300C, 70-80% biochar yield, residence time minutes to hours).

Temperature

- A whitepaper by Pacific Biochar highlights research that finds biochar produced at higher temperatures (>500C) is more durable from a carbon removal perspective. However, increased temperatures generally decrease the biochar yield relative to syngas.

Scale

- Homegrown: This is how biochar production got started. If you search “how to make biochar”, you’ll find guidance on how to burn biomass in a pit in your yard, or how to build or purchase a small system.

- Mobile/Smaller-scale systems: Takachar is an example of a company in this bucket. These are simplified, smaller-scale reactors that can be deployed near a biomass source and are advantageous in rural areas without much infrastructure.

- Industrial Scale: Producing biochar at this scale has benefits with respect to efficiency and consistency, such as leveraging the gases produced in pyrolysis for other purposes (e.g. biomass processing). One example of a company that falls under this category is Carbo Culture.

Output of processes:

Biochar: This is solid carbon that has been produced on a small scale for thousands of years (it is thought that the use of biochar originated with the indigenous production of Terra Preta in the Brazilian Amazon). Research suggests that it can persist in soils for hundreds of years, if not thousands.

Some of biochar’s potential applications include but are not limited to:

- Soil: This is the most well known application of biochar, and includes agriculture, remediation, and green infrastructure applications.

- Building Materials: at this point, there are limited commercial applications of biochar in building materials, though projects do exist. Potential benefits include enhanced strength, fire resistance, and humidity control, among others.

- Do nothing (e.g. bury underground): Self explanatory.

Bio-oil: Bio-oil is often treated as an intermediary to other fuel sources, as it isn’t particularly usable on its own. However, the company Charm Industrial is taking advantage of its properties for high-quality CO2 removal by storing it underground in disposal wells. Bio-oil slowly solidifies over time, which makes it attractive from a carbon removal perspective when pumped underground. At this point, there do not appear to be many other companies that specifically seek to produce bio-oil for the purpose of carbon removal.

Syngas: This is a mixture of gases typically consisting of carbon dioxide, carbon monoxide, methane, and hydrogen. Ideally, this is captured and used in the processing of biomass (e.g. drying the biomass), energy production, or at a minimum burned off to prevent emissions of these gases to the atmosphere.

In summary – the feedstock and processing of that feedstock impact the ratios and qualities of the three outputs, and how those outputs are used ultimately determine the climate impact and any additional benefits potentially involved

Next up – we’ll take a closer look at the business landscape for this space.

About The Author

Christina manages Sales Enablement programs at Instrumental Inc, a cloud manufacturing optimization platform that partners with electronics brands to improve engineering efficiencies and reduce scrap/waste. Her professional background is in energy efficiency, with roles in revenue operations and sales development at Carbon Lighthouse, following an academic background in environmental engineering. Outside of the climate world, she supports the San Francisco Beacon Initiative as a member of their Associate Board, and in her spare time is an avid enthusiast of hip hop and house dance, the outdoors, and good food.