How was your July 4th? 🎆

We recently came across a goldmine of information on how software, technology and data will transform the food and agriculture systems of the future. Check out “Software is Feeding the World,” which looks at issues at the intersection of technology and agriculture & food systems. The newsletter includes conversations with thought leaders in the agritech industry, and topics like automation, sustainable agriculture, smallholder farming in developing countries, business models, history of innovation, policy challenges, carbon markets, etc.

– Swarnav S Pujari

In Your Inbox: A new way to fight wildwires; Using mycelium as a means to reduce plastic pollution

Wildfires are not only devastating to communities and habitats, but also to economies. The need for powerful new firefighting capabilities is higher than it’s ever been, and growing. The urgency to bring more technology to this market has never been stronger.

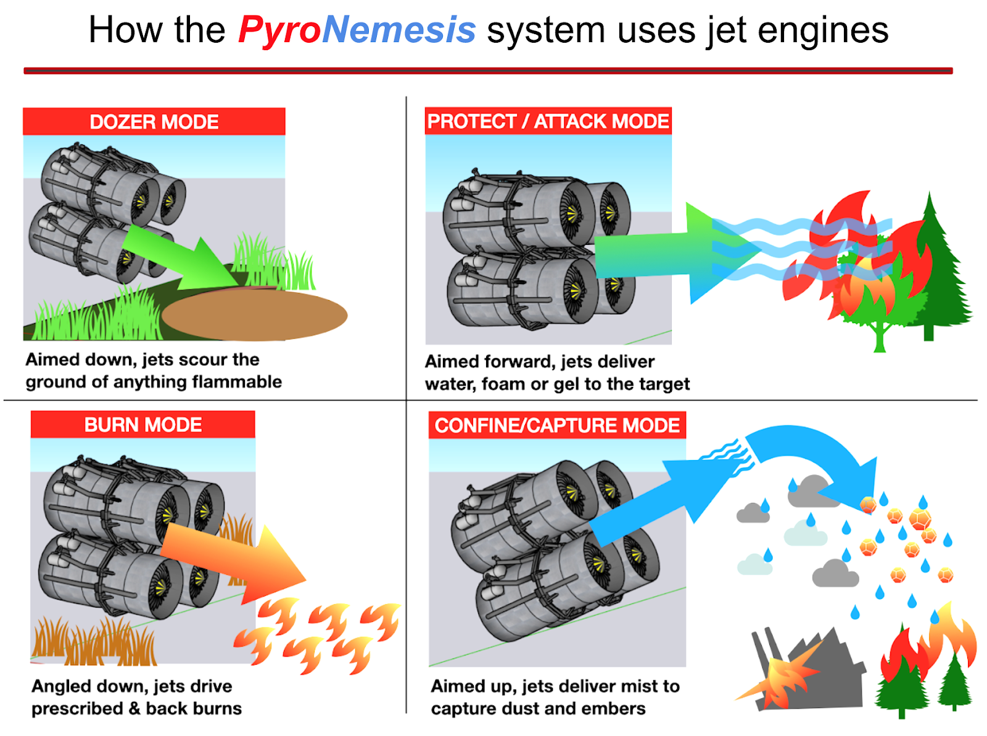

PyroNemesis, a Boulder-based startup, has introduced a modern and substantial new capability to directly attack wildfire, using unique multi-capability technology. PyroNemesis is modifying technology developed and used in Hollywood movies, and putting it in the hands of firefighters, who, with the help of Pyronemesis, will finally be able to control wind, rain and humidity. PyroNemesis technology is essentially a Category 5 hurricane on wheels, putting 250 mile per hour winds and massive rains at firefighter’s disposal.

Drawing on 30 years of experience as a pyrotechnician for stars including Tom Cruise, Steve Wolf,

a frequent fire expert on The Discovery Channel, invented a new technology for wildfire suppression.

My background is in special effects and pyrotechnics for films. I’ve worked on movies with Tom Cruise, Robert De Niro, and Tom Hanks, and for directors including James Cameron. I’ve made a lot of fire on movie sets. More importantly, and relevantly, I was also responsible for putting them out.

I was working with director Sydney Pollack on a movie called “The Firm”, where I made a small fire for him. After filming, Pollack came over and he said, “The fire looked great. You don’t have to put it out, but it can’t stay here.” And that gave me the idea that fire and its components could be moved, because fire emanates from physical fuels. If you can move those fuels or remove any of the factors that are necessary for a fire to survive, (fuel, oxygen, heat, and chemical reaction) you can move fire, or extinguish it outright.

I interviewed hundreds of firefighters, most of whom joked that all they needed to put out a wildfire was the wind to their backs and a good rain. When movie directors need that, they get it, so why, I wondered, shouldn’t firefighters have access to the same or better tools?

I started experimenting with small jet engines as a way to attack fires, to move fuels, and to accelerate controlled burns as a way of creating protective barrier areas. I was looking to build a machine that would attack fire on all of its vulnerable fronts. I found that with the use of powerful air currents and misted chemistries, I could do several things that impacted fire movement.

PyroNemesis leverages technology that has been well proven in both aviation and in forestry – and is derivative of the kind of equipment that we use on movie sets for making wind, rain and hurricanes.

The best metric for impact is relative to what the other tools do and how much they cost per unit of effectiveness, such as cost per linear foot of fireline extinguished, or cost per acre for fire mitigation. For instance, an aerial tanker may do a drop that costs $80,000 for 1,000 linear feet of fire extinguished using roughly 20,000 gallons of fluid. PyroNemesis technology could put out 1,000 feet of fire for about $10,000, (and do so with retardants that are much safer than those currently in use.) Similarly, fire trucks drive down roads spraying water on either side of the roadway, but that’s typically insufficient to stop fire from jumping across the road, because the water doesn’t go far enough to create a large enough gap. PyroNemesis gear can spray fire-killing mists and retardants 600+ feet on either side of the roadway for at-comparable cost, with much greater effectiveness.

Another factor is that our technology allows us to deliver flame retardants to areas that are inaccessible to airplanes and fire trucks. Airplanes can only fly during the day and can’t drop near roads or bodies of water. Fire trucks are largely bound to pavement, so they’ve got to stay on the blacktop and wait for the fire to get to them. PyroNemesis vehicles can deliver retardants, protective gels and mists to places where you can neither drop from an airplane nor access with a fire truck, and can run 24 hours a day.

The best metric for impact is relative to what the other tools do and how much they cost per unit of effectiveness, such as cost per linear foot of fireline extinguished, or cost per acre for fire mitigation. For instance, an aerial tanker may do a drop that costs $80,000 for 1,000 linear feet of fire extinguished using roughly 20,000 gallons of fluid. PyroNemesis technology could put out 1,000 feet of fire for about $10,000, (and do so with retardants that are much safer than those currently in use.) Similarly, fire trucks drive down roads spraying water on either side of the roadway, but that’s typically insufficient to stop fire from jumping across the road, because the water doesn’t go far enough to create a large enough gap. PyroNemesis gear can spray fire-killing mists and retardants 600+ feet on either side of the roadway for at-comparable cost, with much greater effectiveness.

Another factor is that our technology allows us to deliver flame retardants to areas that are inaccessible to airplanes and fire trucks. Airplanes can only fly during the day and can’t drop near roads or bodies of water. Fire trucks are largely bound to pavement, so they’ve got to stay on the blacktop and wait for the fire to get to them. PyroNemesis vehicles can deliver retardants, protective gels and mists to places where you can neither drop from an airplane nor access with a fire truck, and can run 24 hours a day.

Firefighting is an industry that has typically been very slow to change and to adopt new technology. But I’ve always been inspired by something Steve Jobs said when he advised that you don’t have to go up against existing technology, you just have to do something that makes it obsolete. In this case, we’re not planning to eclipse current methods, but to fill in some huge gaps that current methods and tools don’t address.

There are companies like Chubb, AIG and FM Global that have very aggressive wildfire mitigation strategies for their clients. If a wildfire is approaching a client’s $30M home, and an adjuster is about to have to write a huge check for the loss of that home, and instead they could pay PyroNemesis $200,000 to fully protect that property, that should be an easy decision to make. By contrast, adopting a new technology for use on a statewide or federal basis is a multi-committee decision that requires much more time. Partnering with companies that already have relationships and contracts with these agencies is another strategy I’m using to gain traction.

Support has been really great. The concept has been very well received by folks at CAL FIRE, U.S. Forestry and by fire departments around the world – most ask, “Why didn’t someone think of this sooner? And how quickly can we get a fleet of them out here?” But I don’t anticipate selling machines. This is a service-model business, as the complexity of operating and maintaining the equipment is beyond the capability or desire of most fire departments.

We’re working with several supercomputer teams to model the effectiveness of this technology. We’re exploring how to strategically deploy our technology at very specific locations and times in order to keep a fire from entering a particular location, such as a populated area in the midst of a wilderness area. And, If we can’t prevent fire’s entry into an area, we want to delay it, to increase the time people have to evacuate. If we can give people hours to evacuate, rather than minutes, lives will certainly be saved. And once evacuation orders are issued and evacuation routes are defined, we can make that a safer corridor by treating the wilderness on either side of the roads, to keep fire off the road.

Wildfire suppression is just one use of the technology. After a fire, the ground is hard and doesn’t absorb water, which leads to mudslides and flooding. To fix this, you have to introduce chemistries to the soil to make it conducive to absorbing water and supporting new growth. Our technology can help by quickly applying large quantities of reforestation chemicals, soil enhancers, and hydrophilic agents that help draw water to the soil.

Generally, any problem that can be solved with a large, aerosolized distribution of chemistries is a good match for this technology. So, if there is an oil spill and you need to capture and reclaim that oil, we can distribute materials like imbiber beads. We can apply agents for neutralizing pathogens, or suppressing dust. We can even use the cooling effect of our long-range highly directional misting systems to control the flow of lava from volcanoes, turning lava flow into solid walls that cause lava to flow around them.

PyroNemesis is focusing on putting out and controlling the spread of existing fires, and applying long-term retardants to make the next fire season easier to manage. Other enterprises in the industry are looking at software solutions – modeling where the fire is going to go, measuring wind, predicting fire movement, calculating fuel loads, etc., and that’s important, but no amount of data will put out a raging fire. It takes heavy duty physics driven hardware to put out fires. We’re going to get fires whether we predict them or not. The practical question is how are you going to handle fire when it happens? This is the aspect of innovation PyroNemesis is tackling.

Sign up for The Impact and learn the perspectives behind the latest sustainability trends

As reducing plastic pollution and greenhouse emissions from animal agriculture have become priorities in stopping the climate crisis, companies have been searching for material substitutes that can both sustain their business long term as well as promote a sustainable lifestyle for consumers. Ecovative Design is providing that solution through the mycelium, which is the root structure of mushrooms.

Eben Bayer, the CEO and Co-Founder of Ecovative Design, took the time to discuss how his company is using mycelium to help create products that can reduce the use of animal agriculture and plastic.

Founded in 2007, Ecovative is a mycelium technology company that is focused on growing better materials for the food, packaging, and textile industries.

The journey started with a mission to replace materials that humans throw away, such as plastic packaging like styrofoam, that negatively impacts the planet’s ecosystem, as well as to mitigate climate change brought on by industrial animal agriculture to create healthier food options and leather substitutes.

Since then, Ecovative Design has partnered with a range of companies across industries to research and develop new mycelium solutions, such as its next generation Mycelium Foundry that is used to grow mycelium at a commercial scale in the world’s largest vertical mycelium farm. Ecovative Design also developed and licensed mycelium materials technologies around the world, which help distribute our product line to over 32 countries.

Current eco-friendly alternatives come with major trade-offs: they are more expensive, do not perform well, or are difficult to scale.

We help solve this problem by using precise incubation systems and a deep understanding of mycelium’s biology, which our team has been working with over 15 years, to amplify the natural properties of specific strains to fit unique needs for products and customers. Our mycelium foundry uses proprietary biofabrication and vertical farming processes to grow fully formed materials; we do not rely on heavy machinery or non-renewable resources to produce our products . These mycelium materials have structural properties uniquely suited for use in products that replace plastic, styrofoam, leather, and animal agriculture without sacrificing performance or cost

Our focus is currently on three verticals—food, textiles, and packaging. While mycelium can be used for many things, we only work on applications of mycelium that meet the following criteria.

While our focus right now is on packaging, textiles, and food, the company envisions mycelium as a disruptive technology in many industries where pollution, waste, and carbon emissions are a concern.

Across the board, the biggest challenge is proving performance parity with existing materials. Take packaging for example—current options for protective packaging have been perfected over the past half century, and are now extremely cheap and lightweight; but, the long-term environmental impact of this packaging has been ignored.

Historically, the biggest challenge for bio-materials has been producing the materials on a commercial scale. Developing a new material is an expensive and time consuming process, and our team has spent the last 14 years building knowledge and infrastructure to perfect the process and deliver on mycelium’s potential.

Our Mushroom® Packaging had to be as good as, or even better than, conventional packaging to compete. The same challenge is true for the food and textiles sectors—it’s simply not enough to be more sustainable. Our products, first, have to perform and, we’re excited that we now have plenty of empirical evidence to show our mycelium-based products can perform as well as, or even better than, conventional alternatives.

We only target markets where mycelium-based products are able to be equal or exceed the performance of conventional alternatives. Our packaging, textile, and food technologies all fit into this category:

Ecovative Design has a variety of customers across our three verticals of packaging, textiles, and food. Our Mushroom® Packaging is used by many brands including Seedlip, Keap, and Aplós to provide protective packaging for their products.

On the textiles side, we’ve already licensed our technology to Bolt Threads, and are now working with fashion and apparel companies to bring Forager® Hides, Ecovative’s animal-free leather alternative, to more consumers.

On the food side, Atlast Food Co. is working with consumer packaged goods (CPG) brands that are developing plant-based bacon using our mycelium super ingredient, and through our consumer-facing brand, MyEats, we are currently selling limited quantities of MyBacon at Honest Weight Food Co-op, an Albany, NY-based grocer with expanded distribution in 2022.

Ecovative Design holds over 40 patents in 30 different countries and has perfected the science of mycelium through proven, proprietary technology.

Ecovative is the only mycelium company producing market-ready materials at commercial scale. We have over a decade of experience shipping products globally, and have shipped millions of units of packaging worldwide. Our global network of licensees produce millions of pounds of mycelium materials annually across multiple production sites. Together with our partners, Ecovative is responsible for more production than all other mycelium producers combined.

Just as importantly, we are the research leader, kick-starting the field in 2007, and most recently building Mycelium Foundry One, the world’s most advanced mycelium research facility, in 2019. Mycelium Foundry One is capable of high throughput, rapid testing and replication to identify the perfect mycelium strain for the right application. Our team oversees product development all the way from small scale prototyping to commercial scale mycelium material production.

With the $60M raised in new funding in March, the company will be expanding quickly over the next few years. It has been building on more than a decade of experience producing mycelium materials with partners throughout North America, Europe, and Asia. This funding will power Ecovative’s next-generation Mycelium Foundry and support another 10X boost in production.

The team has also spent the last decade assembling the largest mycelium library in the world and is actively exploring the properties of each of those strains. Every mushroom has unique performance characteristics. Some may yield mycelium that is especially dense, tough, or flexible.

Ecovative focuses on customizing mycelium materials to match unique market needs for the partners.

Ecovative Design is taking a lead in the mycelium industry and turning it into another option to help transition our consumer lifestyle into a sustainable one.

There are over 5M species of fungi on Earth, but so far, humans have only discovered less than five percent of them. The potential opportunities of mycelium are untapped as more organizations like Ecovative are discovering new species of fungi as well as their unknown properties with the company’s ever growing mycelium library and rigorous research and development.

As Ecovative Design is able to prove the use of their products for mainstream companies, mycelium may quickly be adopted and embedded in our society before we know it.

If you want to understand more on how the company works with mycelium, check out this recent video from Business Insider.

Editors: Swarnav S Pujari, Daniel Kriozere Writers: Javin Chan

If you aren’t absolutely thrilled with The Impact, reply and let us know why. Or you can unsubscribe from all updates by clicking here.

Copyright © The Impact 2021. All Rights Reserved || 19 Morris Ave, Bldg 128, Brooklyn NY 11205

Develop your market map of up-and-coming climate startups and market opportunities by subscribing to our weekly newsletter for free.